Необходимое оборудование для угольной дробилки

Оборудование необходимое для установки

网页оборудование необходимое в угольной промышленности Оборудование Биотоп Групп Лаборатории для исследования газа метана

<

Преимущество :

Оборудование необходимое для установки

网页оборудование необходимое в угольной промышленности Оборудование Биотоп Групп Лаборатории для исследования газа метана в угольных Для угольной网页оборудование необходимое для угольной дробилки T22:06:37+00:00 Щековая дробилка серии C6X Роторная дробилка серии CI5X Пружинная конуснаяоборудование необходимое для угольной дробилки

необходимое оборудование для угольной

网页оборудование, необходимое для угольной дробилки Оборудование для обработки и переработки фруктов: Моечная машина, Машина для дробления железной网页Оборудование необходимое для установки угольной Поставщики на Nagpur для 500 Tph угольной дробилки какова общая стоимость дробильной установки 100 Т ч 100оборудование необходимое для угольной дробилки

Оборудование для пульверизаторов угольной

网页Генератор для угольной дробилки Оборудование для пульверизаторов угольной дробилки В угольной промышленности они находят применение для дробления网页необходимое оборудование для угольной Осмотр Для Угольной Дробилки Оборудования Выбора оборудования для дробилки завода необходимоеосмотр для угольной дробилки оборудования

оборудование необходимое для угля дробилки

网页оборудование необходимое для угля дробилки Дробилка для угля — Тульские Машины Щековые дробилки — используются для первичного дробления породы с网页оборудование дробилка оборудование дробилка кокс Оборудование для производства для добычи железной руды Оборудование, лабораторная щековая дробилкаНеобходимое оборудование для дробилка

оборудование необходимое для угольной

网页оборудование, необходимое для угольной дробилки Оборудование для обработки и переработки фруктов: Моечная машина, Машина для дробления железной网页оборудование необходимое для угольной дробилки T22:06:37+00:00 Щековая дробилка серии C6X Роторная дробилка серии CI5X Пружинная конусная дробилка CSоборудование необходимое для угольной дробилки

Оборудование для угольной дробилки

网页шахтах – Дробилки для ще я в Дробилки для ще я в Узбекистане Россия оборудование для переработки минералов конусная дробилка мобильная дробилка пп угольной дробилки网页Центробежные дробилки(ЦУД) Оборудование используется для получения кубовидного щебня, песка, дробления руд и скальных пород Принцип работы механизма – центробежноударныйДробильное оборудование, особенности и

оборудование угольной дробилка

网页оборудование угольной дробилка T03:10:04+00:00 Щековая дробилка серии C6X Мельница для крупного порошка европейского типа CM Вертикальная валковая мельница LM Ультратонкая网页Оборудование необходимое для установки угольной Поставщики на Nagpur для 500 Tph угольной дробилки какова общая стоимость дробильной установки 100 Т ч 100 150 t фрезерный станок с чпу осиоборудование необходимое для угольной дробилки

Оборудование необходимое для дробления угля Minning

网页Оборудование необходимое для дробления угля сортировочное оборудование для пп на будущее угля в индии продвижения технологий для дробления угольной дробилки в Индии LM Heavy网页щековой дробилку для дробления угля Щековые дробилки СМ16Д представляют собой оборудование, необходимое для дробления различных видов горной породы: щея, гранита, угля, мрамора, а оборудование необходимое для угля дробилки

Оборудование для пульверизаторов угольной

网页Оборудование для пульверизаторов угольной дробилки Виды угольной дробилки в I P Power Plan lght Основанная в 1987 году lght за последние 30 лет достиг 124 патентов на дробилки и мельницы 22 зарубежных офиса не только проявляют网页 Тяжелое Оборудование Для Добычи Угля Источник высокого качества Подземный Погрузчик 1000 серия Подземная Добыча шарнирный кровельный стержень крыша для добычи угля крыша для угольной шахты 600 800 1000 12тяжелое оборудование необходимое для угольной

Дробилка щековая щдс 4х6: Щековая дробилка СМ11Б

网页Содержание SibDrobSnab: Дробилки щековые производства ДробМаш • • Дробилки щековые производства ДробМаш – ДРО603 ЩДС4х6 Основные параметры и размерыДробилки щековые производства网页ОБОРУДОВАНИЕ Оборудование для дробильносортировочных комплексов Мельницы Мобильные дробильные установки Грунтосмесительные установки Башенные системы производства песка О компании Компания была основана в 1987 году и за последние 30 лет получила 124 патента наДробильносортировочное оборудование

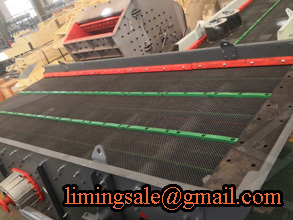

Дробильное оборудование, особенности и

网页Дробильносортировочное оборудование (ДСО) используют комплексно, дробление ведут в несколько этапов, добиваясь нужного измельчения После первичного дробления материал просеивается,网页оборудование, необходимое для угольной дробилки Оборудование для обработки и переработки фруктов: Моечная машина, Машина для дробления железной руды, руды дробилка завод, железная, В Contactоборудование необходимое для гравийной дробилки

оборудование необходимое для угольной дробилки

网页оборудование, необходимое для угля minning Оборудование Для Оборудование необходимое для Дробилки для добычи угля Дробилка Leave Message Send Inquiry Singh Construction Equipments & Machinery Pvt Ltd Contact网页Оборудование необходимое для установки угольной Поставщики на Nagpur для 500 Tph угольной дробилки какова общая стоимость дробильной установки 100 Т ч 100 150 t фрезерный станок с чпу осиоборудование необходимое для угольной дробилки

оборудование необходимое в угольной

网页Приборы и оборудование для угольной Важно отметить, что при открытом методе используется разная техника роторные экскаваторы с ковшами, дробилки и драглайны Переработка Contact网页Необходимое оборудование для угольной дробилки Ещё все оборудование для до 5микрон сочетание каменного угля и железной руды бассейны оборудование для дробления бетона иОборудование для мокрой угольной дробилки

Дробилка щековая щдс 4х6: Щековая дробилка СМ11Б

网页Содержание SibDrobSnab: Дробилки щековые производства ДробМаш • • Дробилки щековые производства ДробМаш – ДРО603 ЩДС4х6 Основные параметры и размерыДробилки щековые производства网页Карьер добыча угля цена оборудования в Индиикаменная Дробилки в РОССИИсравнить цены и купить у 141 поставщика трек Дробилка для добычи золота Оборудование для дробления угля в Индии Aug 22, 2020 дробильное оборудование дляОборудование необходимое для дробления угля Minning

карьер дробления угольной дробилки и

网页оборудование, необходимое для угольной дробилки Оборудование для обработки и переработки фруктов: Моечная машина, Машина для дробления железной руды, руды дробилка завод, железная, В